Image Source: MDPI

Image Source: MDPI

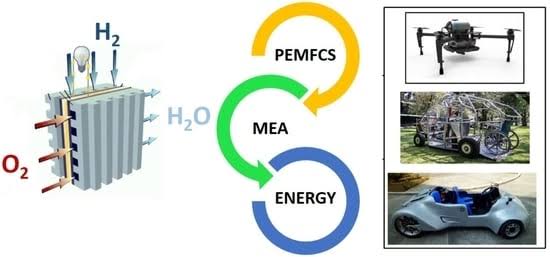

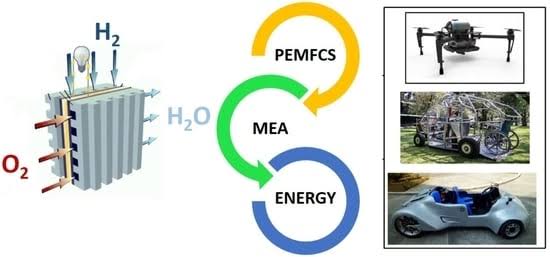

Researchers have unveiled a redesigned flow-channel architecture for proton-exchange membrane fuel cells (PEMFCs), showing significant gains in power density, water management, and reactant distribution—key hurdles in scaling clean energy systems.

What’s New in the Design

-

The study compared three models: traditional straight channels, inclined cross-section channels, and a new variable cross-section flow channel

-

Under high humidity conditions, the variable cross-section design delivered:

-

7.1% higher power density than traditional channels

-

Improved drainage capacity and reduced voltage loss at high current densities

-

The inclined cross-section model also outperformed conventional designs, with a 4.2% power density increase

Why It Matters

-

PEMFCs are prized for their low emissions and high efficiency, but water buildup and uneven gas flow often limit performance

-

The new channel geometry helps:

-

Prevent flooding by enhancing water removal

-

Maintain uniform reactant distribution across the membrane

-

Reduce pressure drop and energy loss during operation

Simulation and Testing Insights

-

Researchers used ANSYS CFD modeling to simulate gas flow, humidity control, and current density across different channel designs

-

The optimized channels showed better performance at elevated temperatures and pressures, especially under full-humidity conditions

-

Future iterations may include 3D modeling and real-world testing to validate lab results

Looking Ahead

-

These findings could influence next-gen fuel cell stacks for electric vehicles, portable power systems, and grid storage

-

The design also opens doors for topology optimization in other clean energy devices

Sources: Journal of Materials Science, MDPI, Springer, RSC Publishing, ResearchGate.

Advertisement

Advertisement