Image Source: India Today

Image Source: India Today

In a pioneering advance poised to redefine metallurgy, scientists at Caltech have developed a revolutionary 3D printing technique that allows metal objects to be printed atom by atom with unprecedented control over their chemical composition and microstructure. This breakthrough unlocks the potential to create ultra-strong, lightweight, and highly customizable alloys tailored to specific industrial and biomedical applications.

Key Highlights: The New Frontier in Metal 3D Printing

The technique, detailed in the journal Small, is an extension of hydrogel-infusion additive manufacturing (HIAM), where scientists first 3D print a hydrogel scaffold infused with metal ions.

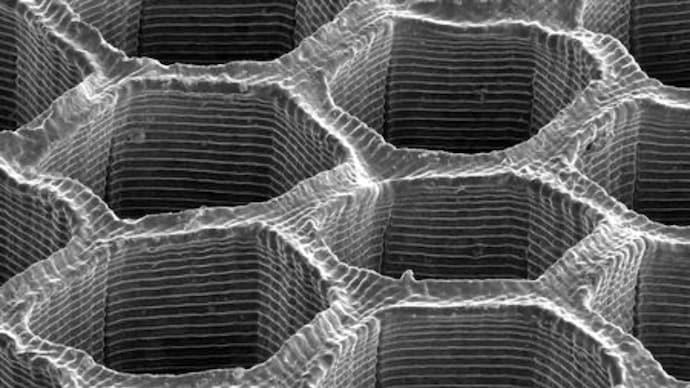

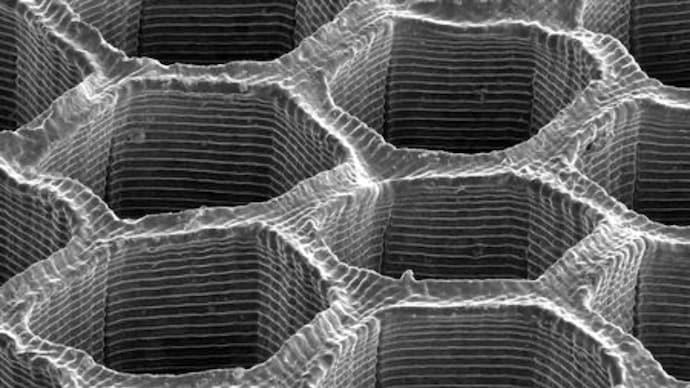

After burning off the organic material, they obtain a delicate metal oxide structure that is then reductively annealed to remove oxygen, leaving behind a customized metallic alloy precisely shaped as designed.

Unlike traditional metallurgy, which struggles to vary alloy compositions quickly or precisely, this method allows scientists to dial in complex metals with any desired chemical ratios and intricate microstructures.

A key demonstration involved copper-nickel alloys of varying compositions, such as Cu12Ni88, which exhibited nearly four times higher strength than variants with different metal ratios—a result confirmed through advanced electron microscopy.

Why This Breakthrough Matters

The ability to 3D print metals atom by atom while customizing microstructures enables the creation of components that are stronger, lighter, and more resilient than conventional materials.

Embedded nanoscale oxide particles trapped within the metal act as internal reinforcements, improving hardness by disrupting typical metal deformation pathways.

This kind of precise control challenges long-held assumptions in metallurgy, showing that composition and hierarchical architecture heavily influence material strength beyond grain size alone.

The new process opens avenues for designing alloys optimized for extreme environments such as aerospace, biomedical implants, and advanced industrial machinery.

How the Process Works

3D Printing Hydrogel Scaffold: Scientists print a flexible hydrogel structure in the desired shape.

Metal Ion Infusion: The scaffold is soaked in metal salt solutions containing ions of target metals (e.g., copper, nickel).

Calcination: The hydrogel is heated to burn away organic material, leaving behind a metal oxide framework.

Reductive Annealing: Heating in a hydrogen atmosphere removes oxygen, forming a dense metal alloy with unique microstructure.

Future Impact and Applications

Aerospace components can be designed with improved strength-to-weight ratios, increasing efficiency and durability.

Biocompatible and mechanically robust medical implants can be produced, tailored precisely to patients’ needs.

Customized industrial tools and parts with enhanced wear resistance and toughness will improve machinery longevity.

The technology enables rapid prototyping and manufacturing flexibility, reducing dependency on traditional forging and casting processes.

Conclusion

This atom-by-atom 3D printing breakthrough epitomizes material science’s leap into the 21st century, where precision engineering at the nanoscale empowers bespoke metal components with superior properties. The ability to control alloy chemistry and microstructure simultaneously offers vast new possibilities for technology, medicine, and manufacturing, heralding a new era of stronger, lighter, and smarter materials.

Sources: India Today, Small Journal

Advertisement

Advertisement